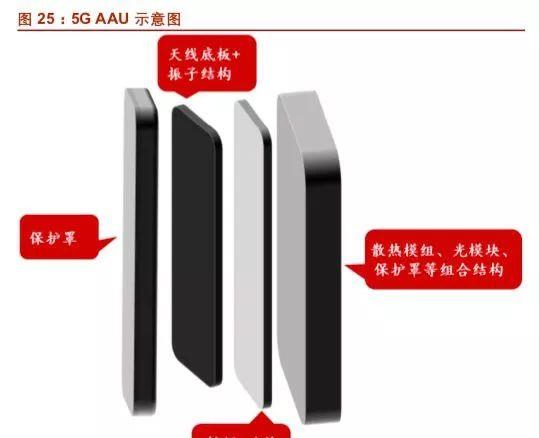

With the introduction of large-scale antenna technology to 5g base station, the volume, weight and heat dissipation of AAU are challenged. How to find a balance point among the three and do well in AAU design requires the use of a variety of new technologies, new processes and new materials. Before we talk about the thermal design of AAU to be launched today, let's take a look at the structure of AAU.

5GAAU

As the main equipment of base station, AAU can be divided into four parts:

(1) The protective cover adopts a mixture of glass fiber and new materials, which is 40% lighter than the original. In addition, the signal penetration loss is reduced by 90%. The air permeability is stronger, the surface is not easy to age, and the service life is longer. However, the traditional plastic materials will become brittle and easy to wear after a long time.

(2) Compared with 4G, the combination structure of antenna base plate and vibrator changes greatly, the material is high frequency, and the number of channels is also increased. The base plate of 5gaau antenna is mainly high frequency PCB, which is the carrier of antenna vibrator and is responsible for transmitting signals. 5gaau antenna vibrator is also greatly upgraded compared with 4G. In the traditional scheme, a vibrator has multiple parts. Now 5g integrates several vibrators into one part through processing technology, reducing the number of solder joints, reducing the failure rate. The vibrator is composed of plastic, metal coating and PCB.

(3) In the 5g scheme, for the combination structure of RF + power amplifier, take the leading manufacturer as an example, the RF part and antenna part are integrated in AAU, and the RF part is based on a multi-layer PCB with if chip, filter, power amplifier and so on.

The power amplifier chip adopts gallium nitride technology, requires several PCBs as the carrier, and then combines with the RF PCB bottom plate. Combining with the software algorithm, the power amplifier efficiency can be increased by 10% (compared with the average level of other 5gaau schemes in the industry).

AAU intermediate frequency chip adopts ASIC developed by itself, and its performance is also optimized.

In the aspect of ceramic dielectric filter, compared with the original metal cavity filter, the weight and volume of single device are reduced by about 40%, and the number of power amplifiers is increased correspondingly (one filter corresponds to one power amplifier).

(4) Combined structure of heat dissipation module, optical module and protective cover:

Due to the changes of 5g structure and antenna, one of the main changes of AAU compared with 4G scheme is the upgrade of modules such as heat dissipation.

Next, let's see what are the cooling schemes of AAU?

AAU traditional heat dissipation scheme

1. To reduce the temperature difference between the chip and the shell, high heat conduction interface material and heat bridge heat conduction block or heat pipe are used;

2. Reduce the surface temperature of the shell, increase the shell volume and surface area of the equipment;

3. Improve the temperature uniformity of the shell, use cast aluminum to thicken the shell.

In practical products, the improvement effect of scheme 1 is limited. When the shell is exposed to sunlight, the surface temperature can be as high as 60 ℃ to 90 ℃. However, the TC of many chips is required to be within 90 ℃, which will not meet the heat dissipation requirements; for scheme 2 and scheme 3, the product's appearance size and product weight are generally limited, which cannot be increased at will. Therefore, 5g cooling will be a great challenge, which requires more effective cooling design.

New cooling scheme of AAU base station

The heat generated by the internal heating module of the base station will increase the temperature in the sealed chamber. When the temperature is the same, it will be transmitted to the shell for heat convection through air. AAU heat dissipation can start with new materials, new structure design and new heat dissipation scheme.

(1) New cooling scheme, liquid cooling.

Liquid cooling and heat dissipation module: there is a special heat dissipation liquid under the heat conduction pipe connected with the heat sink. Its boiling point is relatively low. After the heat is absorbed, it will evaporate to the top. After the heat is dissipated, it will liquefy again and return to the original place, so as to improve the heat dissipation efficiency.

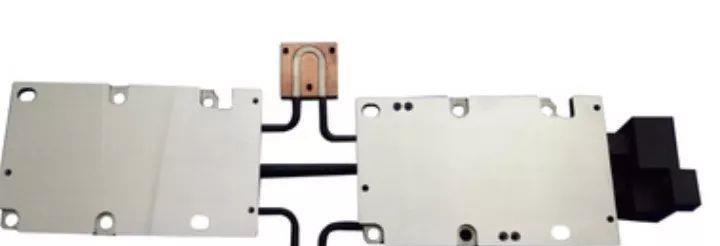

The picture shows the liquid cooling and heat dissipation module with auxiliary plate

However, due to the interface thermal resistance between the rigid material and the heat sink, Tim material must be used inside. Such as heat conducting gel, thermal conductive silicone grease, thermal conductive gasket, etc.

In terms of optical module, it has an optimal operating temperature range. AAU's outdoor working temperature range changes greatly, such as the cold climate in Northeast China and the hot climate in South China. Therefore, new materials are used around the optical module. The temperature of the optical module can be adjusted by controlling the incoming and outgoing direction of the material current. The temperature can be increased to 30 degrees, and the temperature can be reduced to 10 degrees, which is equivalent to "air conditioning".

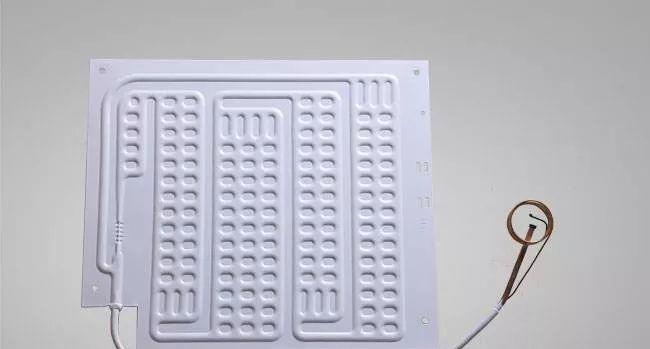

(2) New materials. In addition to the Tim, heat dissipation materials and schemes used in AAU, semi-solid die casting has the advantages of light weight and good heat dissipation performance, and the expansion plate has the advantages of high heat conduction efficiency and fast cooling speed. Combining the heat dissipation devices of semi-solid die casting and expansion plate, it is expected to greatly improve the heat dissipation value of 5g base station.

The picture shows the expansion plate

(3) New structural design. In addition, the manufacturer optimizes the overall volume and weight through structural innovation design on AAU radiator structure, introduces new technology, and realizes lightweight on the overall structure. For example, the traditional design of the cooling teeth, the upper part of the lower heat diffusion, resulting in high temperature of the upper part of the cooling teeth structure, reduce the cooling efficiency, become the bottleneck of cooling. ZTE's unique v-tooth structure design improves the cooling air flow, so that the cold air enters in front of both sides and exits, avoiding thermal cascade, and the cooling is increased by 20%, becoming the industry's first.

The figure shows the radiator of v-tooth structure design

AAU cooling is not good, which will lead to the increase of equipment power consumption, which is a severe challenge for operators, and also an important obstacle for us to promote 5g construction. If the problem of heat dissipation cannot be effectively solved, the implementation and long-term development of 5g will be affected.